What is the definition of Geometallurgy?

Geometallurgy is the practice of incorporating metallurgical characteristics into geology and mining block models to allow more accurate prediction of ore processing characteristics from the models.

What is the key aim of Geometallurgy?

The key aim is to maximise the value of the ore body by optimising the value chain - mining, processing, and tailings disposal. Geometallurgy is a powerful tool for increasing value through improved management of ore variability.

How is Geometallurgy implemented?

As the mining project is progressed through the concept, prefeasibility and feasibility stages increasing amounts of ore body information will be generated. The test results for each sample are added to the block model. Typical information includes geological, geotechnical, chemical, mineralogical and metallurgical testwork information.

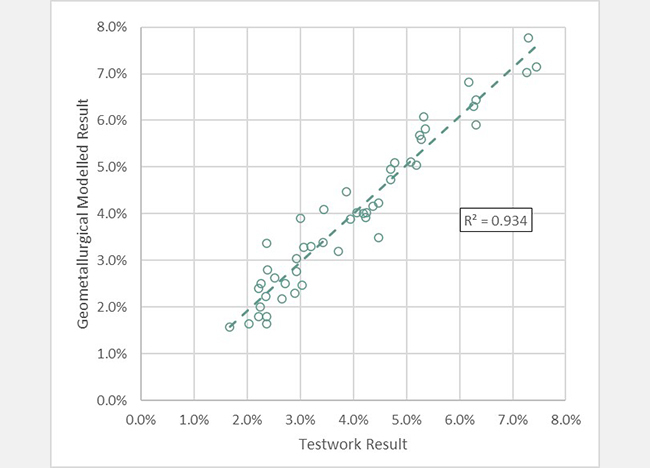

Data and statistical analysis are performed with the aim of developing algorithms for predicting production data, required for project value estimation and project value optimisation.

Examples of output data include: grade and recovery, penalty element feed concentration limits, comminution power requirement, optimum process equipment set points, tailings environmental markers and schedules of concentrate production. Typically, separate algorithms will be developed for different ore types to allow accurate predictions to be made for each ore type. Statistical analysis can be used to provide confidence limits around the predicted data.

How does Geometallurgy assist in mine planning?

The mine block model would be run using additional constraints (e.g. ore hardness or penalty element grades) and different mining sequences. The predicted production data from the geometallurgical prediction algorithms can then be fed to financial models. This will allow the optimum mine design to be quickly identified at an acceptable risk incorporating mining, geological and metallurgical aspects.

How does Geometallurgy assist in process operations?

When the mine is in production the geometallurgical model can be used to reduce ore variability to the process plant and provide ore body information to the metallurgist that allows the plant to be optimised for the ore type as it is fed to the plant. Additionally, concentrate production predictions from geometallurgical modelling are used as an input for producing product shipping schedules.

What is the difference between a geological domain and a metallurgical domain?

Metallurgical domains are based on an ore processing prediction algorithm applied to ore types with measurable characteristics that can predict process performance irrespective of spatial location. A geological domain applies to ore that is located spatially in the orebody that has particular geological (lithological) characteristics. The geological and metallurgical domains may be the same if the geological domain fits with a metallurgical prediction algorithm with high confidence. Similarly, geotechnical domains may be developed in block models based on rock strength characteristics.

What are key factors that lead to successful implementation of Geometallurgy?

- The geometallurgical database is best planned as part of the geological and mine model development.

- Establishing project value drivers in the block model planning stage and consider data collection to allow modelling of the value driver. For example:

- Deleterious elements which are not necessarily modelled with the primary commodity however can play an important role in the processing plant operation and concentrate specification (and payability).

- Consider whether environmental markers for tailings and waste rock are to be captured as a geometallurgical output. For example:

- The modelling of sulphur may need to be extended to include the waste zone and modelling should not be isolated to the ore zone only.

- Particular attention needs to be paid to planning, execution, and evaluation of metallurgical testwork programs to obtain adequate information on different ore characteristics and ore body locations is captured.

- All stakeholders in the value adding chain require a good shared knowledge of the purpose and functionality of the geometallurgical model and the acceptable level of uncertainty for the project's stage of development.

- Input data needs to be documented and auditable.

- Data needs to be stored to allow efficient data input, retrieval, and processing with a skilled user available to support other users.

- Support from personnel who have well developed metallurgical and data analysis skills is essential in the best use of the geometallurgical data.

- The model should be assessed to identify gaps in orebody knowledge that need to be addressed to improve the model output.

What happens if I do not implement Geometallurgy in my Geological and Mine Models?

Powerful mine database modelling tools have allowed metallurgical information to be input into geological and mine models and processed at a small, or no incremental cost compared to methods used before computer modelling was available.

The alternative to using a geometallurgical model is to predict process plant performance based purely on predicted feed grades. As there are a large number of mineralogical variables plant performance would deviate from the grade-based prediction.

Process plants perform best with steady operation so plant performance would be adversely affected if continuous changes are being implemented to overcome metallurgical variances in the feed. Implementation of Geometallurgy has become well-established as a well justified method for mining organisations to make best use of their orebody knowledge and maximise the output from a resource.

How can Independent Metallurgical Operations (IMO) assist with developing ore body knowledge?

IMO has an experienced team of metallurgists that provide metallurgical support for all stages of metallurgical project development and operation.

IMO's services include:

- Collaborating with all stake holders to identify sample and testwork requirements to obtain adequate metallurgical knowledge, at the lowest cost, for the stage of project development that is being undertaken.

- Plan and manage testwork programs to ensure the correct testwork is completed in a timely and accurate manner at a competitive price.

- Perform data analysis and reporting using the best available expertise and tools to identify metallurgical domains, prediction algorithms and provide statistical analysis for input into geometallurgical databases.

- Recommend the metallurgical work required for the next stage of project development if required to further refine the geometallurgical models.

- Perform due diligence studies on metallurgical project work, using suitably accredited personnel.

- Provide metallurgical labour and project support for existing operations.

Examples of Where Geometallurgical Models Have Added Project Value

1. Blending, Zn/Cu (Ag) project producing a separate Zn con and Cu con:

The recovery algorithm was a non-linear relation where below a threshold feed grade the recoverable metal dropped off. To maximise the project economics, it was not appropriate to consider the traditional ‘cut-off grade' as this would eliminate a significant portion of isolated sub-economic material. The problem became an exercise of designating appropriate bins into which to deliver mined material (this has its own spatial and material management issues) and the sub-economic material is blended with higher grade material to deliver above cut-off.

2. Deleterious elements:

A blending strategy for a copper concentrate producer was developed in order to minimise the bismuth grade reporting to the copper concentrate. A significant increase in bismuth concentrate grade was observed over a specific bismuth feed grade. A blending strategy was put in place to ensure the penalty element payability was reduced, minimising treatment charges whilst maximising feed to the process plant.