Swick's History

Since initially commencing as a longhole underground production contractor in 1997, the company has supplied drilling services to some of the most well-known and respected global mining companies across Australia, Europe, and North America.

In early 2004 Kent Swick (Founder and Managing Director) saw an opportunity to grow and expand his business by entering the underground diamond drilling market. Being a mechanical engineer who was used to working with large mobile mining fleet, it was surprising to him to see that the underground core drills were skid based and very tedious and time consuming to move around the mine.

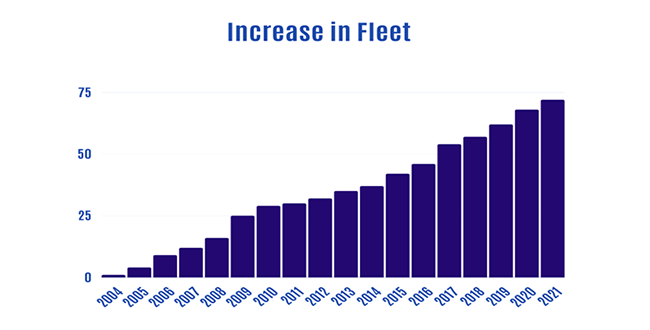

As a result, Swick was able to quickly generate a competitive advantage by placing underground diamond drill rig components on a mobile single boom development jumbo and the Swick mobile diamond drill was born. Swick's current workforce is now in excess of 600 employees with a fleet of 77 underground drill rigs globally.

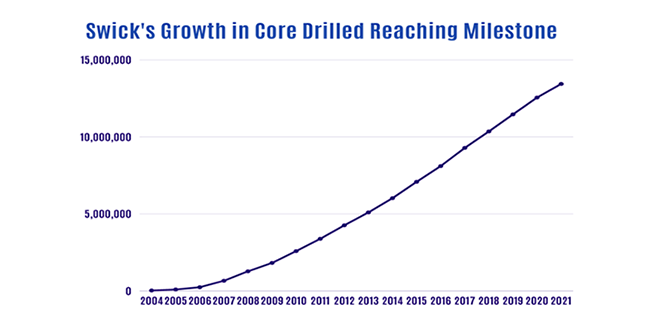

Swick's first underground diamond coring client was Reliance Nickel at the Beta Hunt mine in Kambalda, Western Australia has since worked with 52 individual clients and has reached the incredible milestone of ‘drilling through the Earth' - a total of 12,742,000 metres of core drilled as of March 2021.

To put that into perspective:

- The total weight of that core would equate to around 100,000 tonnes (all handled by hand)

- To fly over that amount of core at cruising speed in an A380 jet would take over 14 hours

- Swick has consumed over 100,000 drill bits to meet that goal

- To achieve that milestone around 6,375 rig months have been drilled or 531 rig years (24 hours a day, 365 days a year)

- With 2 men per shift that's 9.33 million manhours of hard work by the specialist underground crews (a huge effort and a lot of wages)

Reaching the distance of 12,742,000 metres has also come with many challenges: intensive underground grade control drilling, underground exploration drilling, navigational drilling, geotechnical and geophysical engineering/service/paste hole drilling, water control drilling, and gas control drilling.

Kent Swick's personal objective was to make a difference to the underground mining sector and Swick will continue with its objectives to continually improve the safety and productivity of the underground diamond drilling industry. Swick achieves this by supplying a high level of professionalism, reliable performance, strong client relationships and invests heavily in the training and development of its staff. Swick has a strong engineering acumen in the business and has constructed its own drill rigs since 2004 and invests heavily in research and development of drilling equipment and systems. Providing safe, reliable and efficient drilling helps our clients execute their mine plans with less unknowns, producing a longer sustainable mine life.

The above graph represents the climb in metres to meet the milestone 12,742,000 metres.

Since 2004 Swick has increased rig numbers throughout its journey, currently 72 rigs within the fleet with additional builds scheduled to meet market requirements.

The key part of any business is its people, and Swick aims to ensure our crews feel supported and part of our global family. Swick's retention of staff in 2021 has seen over 100 employees inducted into the 10 Year club which helps to maintain Swick's core values. Swick's reputation for creating the best drillers within the industry through its intensive training packages has strengthened the entire market and are highly sought after by our competitors.

Swick understands that innovation is the key to our continued success as market leaders in the Drilling industry. Innovation has not been reserved for just our equipment. Our award-winning Induction Facility has improved staff retention and set the foundation for strong safety and reporting culture. Innovation in our equipment design will ensure continued success in safety and further reduce risk and injuries to our staff.

Our partnerships with clients have resulted in the successful delivery of numerous major R&D initiatives that have greatly influenced the global underground diamond drilling industry. We continue to develop new innovative solutions to mitigate safety hazards, maximise productivity and reduce crew fatigue. Swick, with all its innovations and advancements, has increased productivity by 17% since 2016. In a work environment that only gets deeper and more complex each year, that's a solid achievement.

Swick team inspecting core samples, supplying a quality product to our clients.

A great example of the constantly evolving improvements through rig design has seen Swick recently complete an outstanding shift drilling 200m for the first time in its unique history, there are many elements to achieving this amazing effort, forward planning, time management and clear communication with Driller and Offsider optimizing the Swick's GennII innovation.

Swick's new dedicated deep drilling division, DeepEX, can drill diamond drill holes to over 2,000m from a standard underground drill site. The goal of DeepEX is to meet the needs of Swick's customers as mines get deeper and drilling exploration holes from surface become less applicable due to depth, angle of attack, permitting or access.

Operating an underground DeepEX drill rig is done at a significantly lower cost than surface rigs so shallower holes at a much lower cost per metre is expected to attract customers and allow optionality for miners when considering targeting extensions to their mines.

More information on Swick's services can be found at: www.swickmining.com.